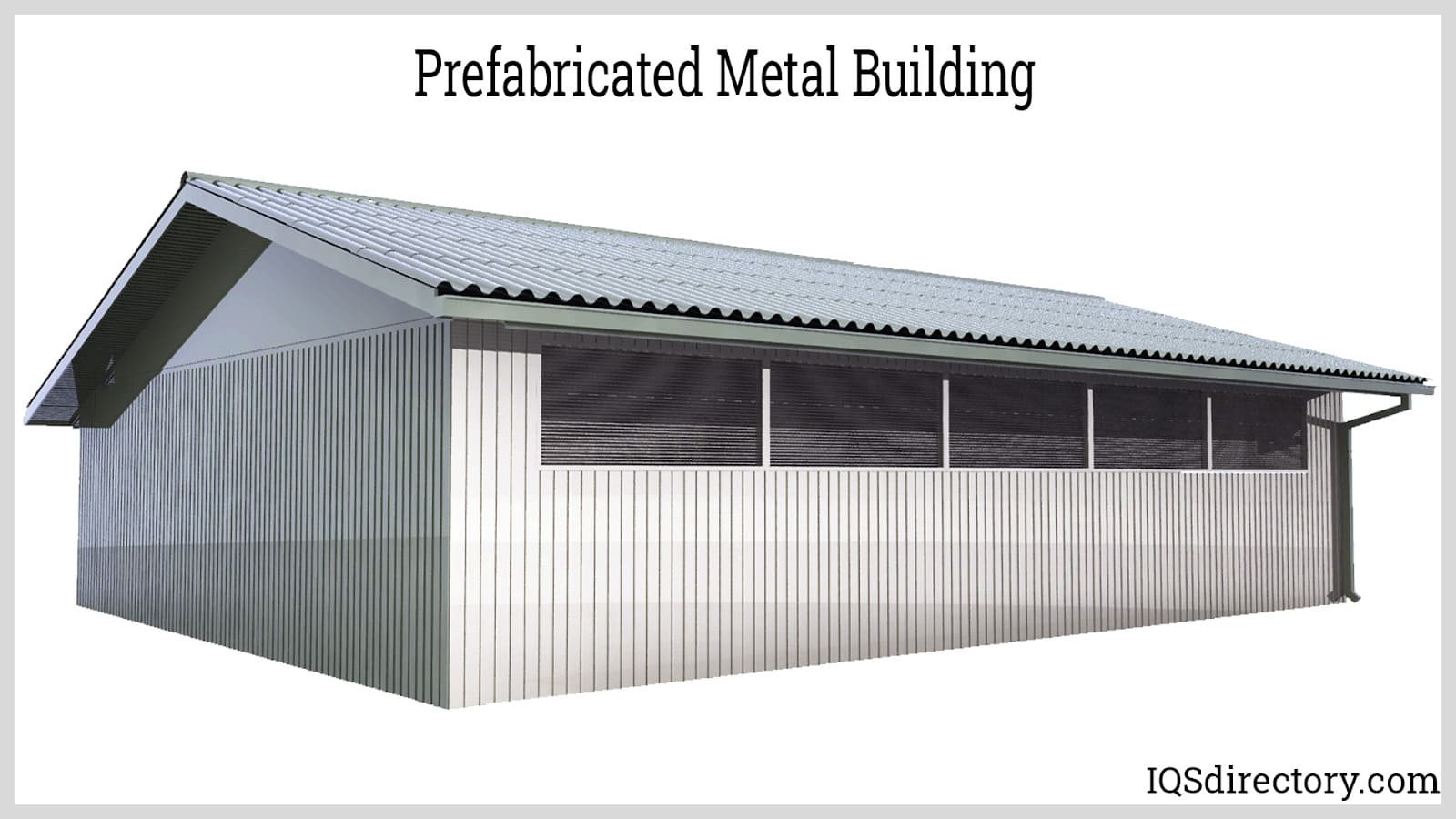

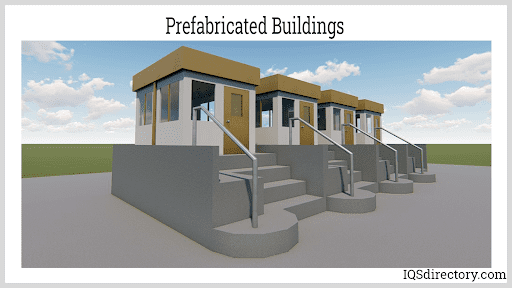

A prefabricated building is made of factory-made components transported and built on-site. Construction manufacturers use this approach often because it’s affordable, reusable, and fast. Prefabrication is more efficient than traditional on-site construction because the prefabricated pieces are uniform. Most buildings’ walls, roofs, and floors are made of repeating units, so it’s easy to create an effective manufacturing process. Read More…

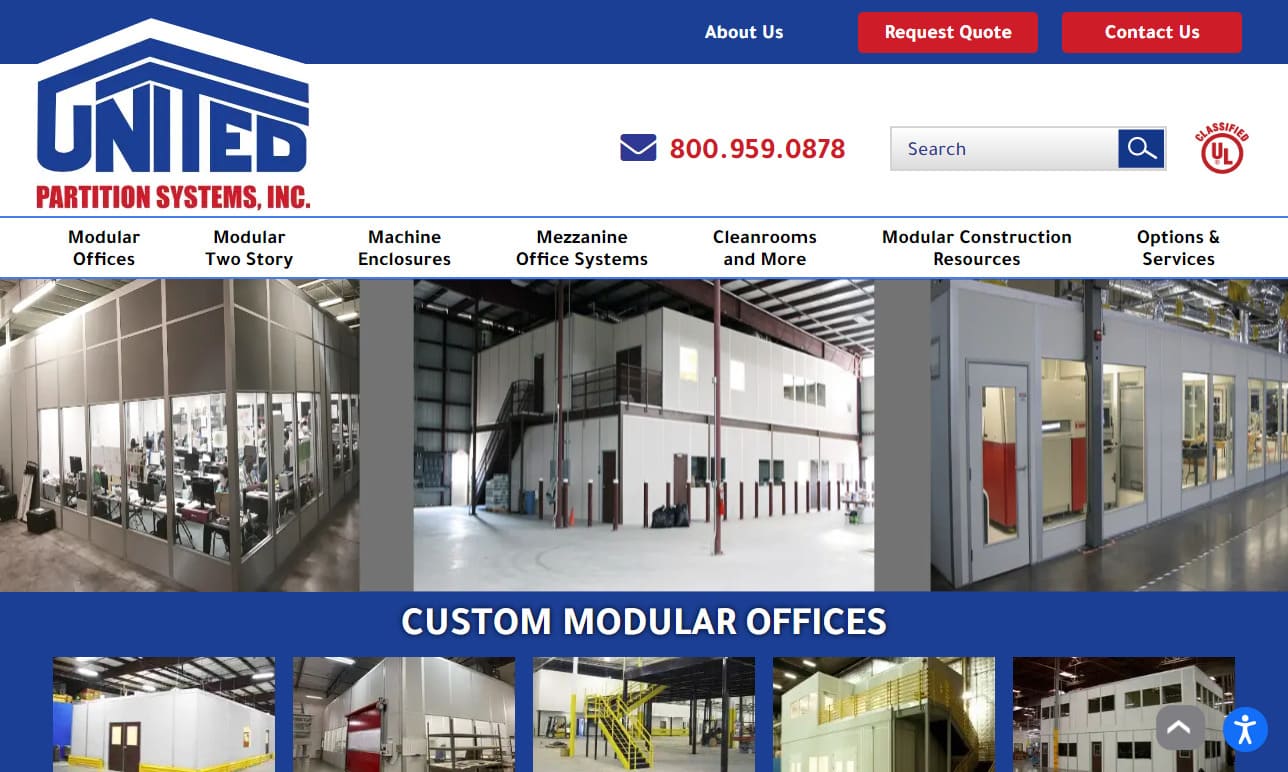

As a modular building manufacturer, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

We offer a wide variety of affordable modular buildings for your convenience. Our engineers are determined to bring you a product with a great value and exceptional customer service. We have been around since 1954 providing portable buildings that are made out of steel.

Our booths and partitions are available in solid surface, stainless steel, solid plastic, solid phenolic, high pressure laminate, and metal powder coated. Our washroom accessories also include combo towel waste units, paper towel dispensers, waste receptacles, soap dispensers, mirrors, warm air hand dryers, toilet tissue dispensers, toilet seat cover dispensers, grab bars, bathroom accessories,...

Morgan Buildings can meet just about any modular building need. For over 60 years and 3 generations Morgan has been a pioneer and leader in modular design and construction. As a fully integrated family-operated company we design, build, transport and install modular buildings around the country and the world. From guard houses to 2-story housing complexes and everything in between we have the...

At Boxx Modular, we specialize in delivering innovative modular building solutions tailored to meet the diverse needs of our clients. With years of experience in the industry, we've established ourselves as pioneers in the field, continuously pushing the boundaries of what's possible with modular construction. Our extensive range of products encompasses a wide variety of modular buildings,...

If you are in need of a modular building then you have come to the right place. Customer satisfaction is paramount to our company and we take extra steps to make your experience with us a positive one. We are recognized as a business leader and our success is based off your success. Contact us today for your next project and let us add you to our list of satisfied customers.

More Prefabricated Building Manufacturers

Components of Prefabricated Buildings

Prefabricated Modules

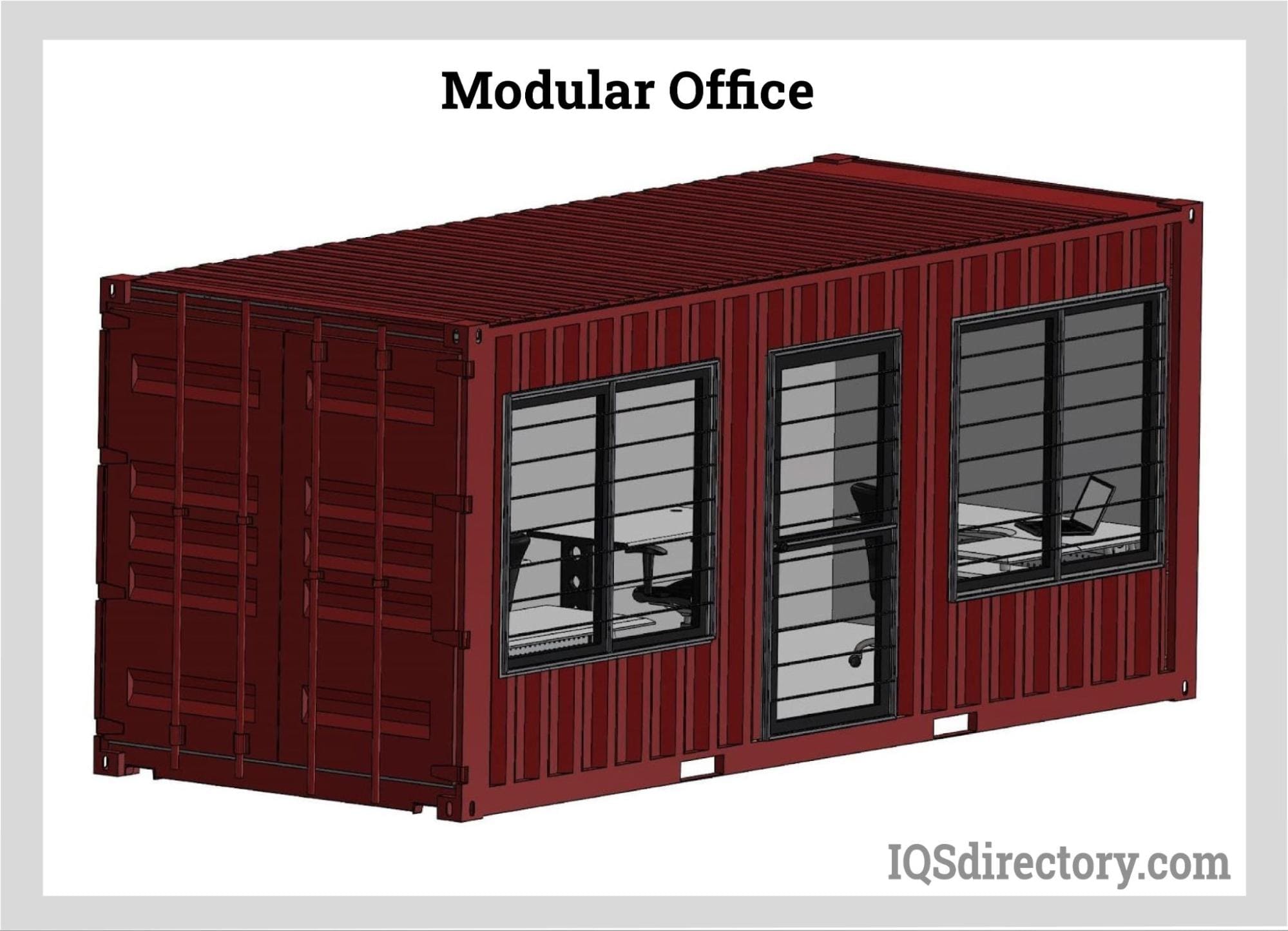

Prefabricated modules consist of four shop-assembled panels, while the entire building is made up of several stacked modules. Inter-module connectors, bolted on site, are used to link these modules. For this reason, prefabricated buildings are also referred to as "modular buildings.” A modular building has all the benefits of a prefabricated building, and a single module can serve as the entire structure with minor site preparation. Modular structures come in various constructions.

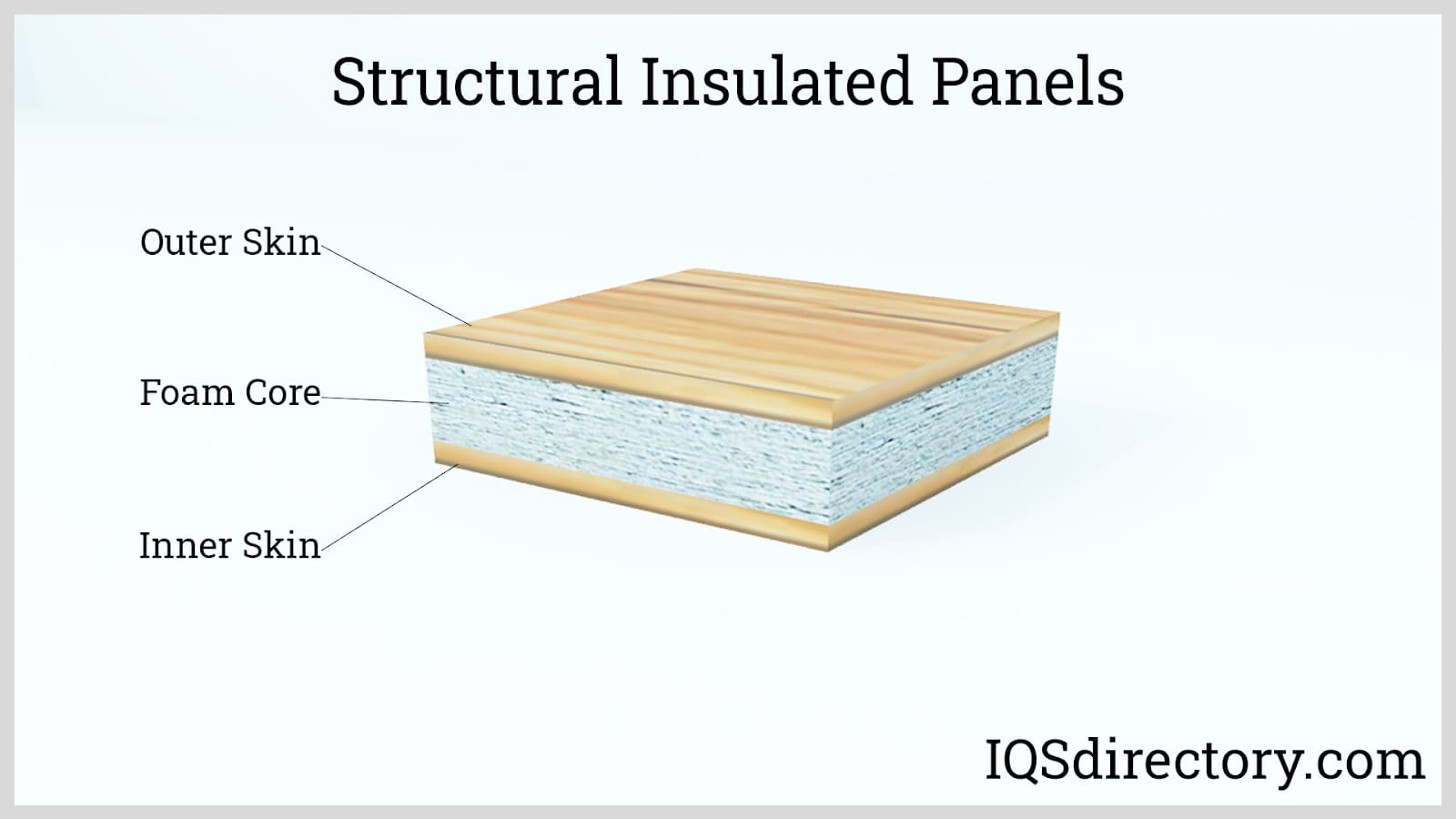

Prefabricated Panels

Prefabricated panels are two-dimensional components assembled on-site to create buildings. In comparison to modular prefabricated buildings, they demand more on-site labor. These parts are frequently offered as sub-assemblies with pre-installed features like windows, doors, and insulation. Additional components can be added on-site after installation. Panels can also be delivered as basic structural frameworks. Prefabricated panel types differ in terms of form and substance.

Types of Prefabricated Buildings

Fiberglass Prefabricated Buildings

Because it is lightweight and strong, fiberglass is utilized to construct prefabricated houses. Fiberglass is mold and rust-proof; therefore, it is ideal for wet outdoor environments. Fiberglass retains its strength in extreme wind, heat, and cold, so it is often used as a wall cladding material in prefabricated buildings.

Fiberglass is available in a wide variety of shapes and patterns. Because of its flexible nature and plastic composite foundation material, fiberglass prefabricated structures' strength, longevity, and aesthetic appeal are all influenced by their resistance to tensile stress. In addition, the superb structural stability and R-18 and R-24-rated insulation offered by fiberglass materials are outstanding.

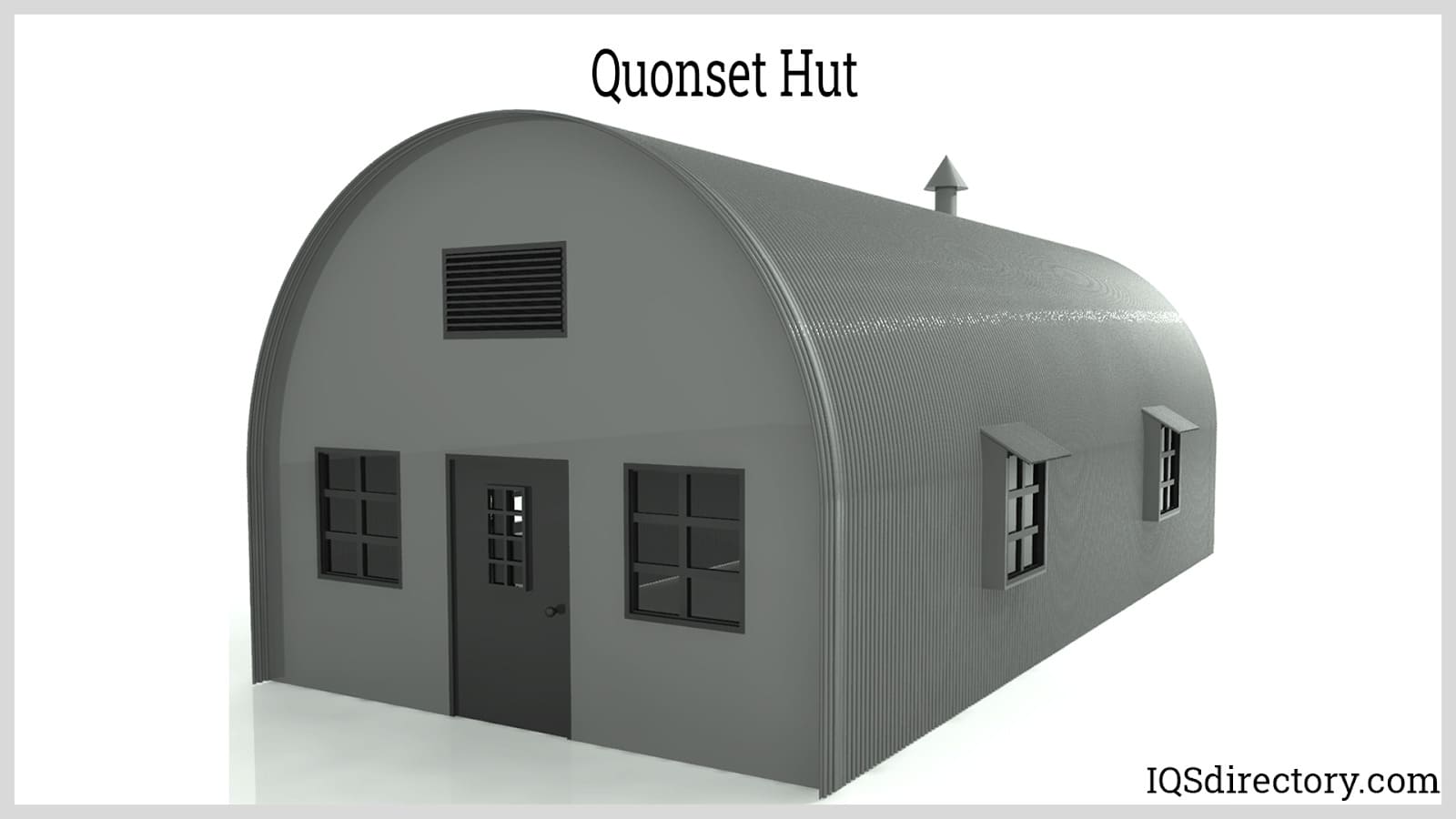

Quonset Prefabricated Buildings

Quonset huts are dome-shaped, prefabricated structures often made of steel alloys. Quonset huts (also called arch steel buildings) are named for the location they were first used, at Quonset Point in Rhode Island. In addition, Quonset huts are affordable, low maintenance, and weather-resistant.

One of the distinctive features of Quonset huts is their identical surface and structure. The galvanized steel arch in a Quonset hut provides structural support and an open design without interior supports crowding the space on the inside. Corrugated panels are used on various surfaces to strengthen the arches. The segments and arches are fastened with bolts, and the arches are secured to the concrete slab. The arches can be lined up without being twisted into position thanks to a connective base plate.

Advantages of Prefabricated Buildings

- Prefabricated buildings are an effective use of raw materials. Conventional construction produces more waste materials and transient elements discarded after construction, including formwork, quick fasteners, jigs, and fixtures. Prefabricated buildings, however, are mobile enough to repurpose.

- Prefabricated buildings save time. Traditional building tasks can be finished in six to nine months. Prefabrication manufacturers can finish these projects in half the time and with the same quality, which results in cost savings and quick structural implementation. In addition, prefabricated buildings can be customized and tailored to each project, necessitating careful engineering and design.

- Some prefabricated structures are intended to be transient. These are preferred when project-based work is involved, such as in building work, remote healthcare services, research, etc. Prefabricated structures are simple to disassemble and move to other locations. Additionally, this functionality ensures that the job site is maintained and altered as little as possible.

Choosing the Right Prefabricated Building Manufacturer

To ensure you have the most productive outcome when purchasing a prefabricated building from a prefabricated building manufacturer, it is important to compare several companies using our directory of prefabricated building manufacturers. Each prefabricated building manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each prefabricated building manufacturer business using our proprietary website previewer to quickly learn what each manufacturer specializes in. Then, use our simple RFQ form to contact multiple prefabricated building companies with the same form.

55 Gallon Drums

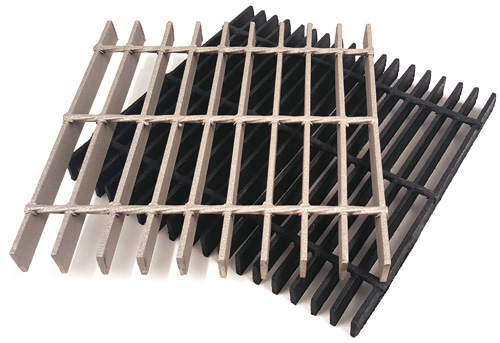

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

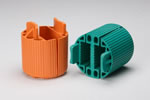

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services