Guard houses are an essential component of any secure facility. They provide a designated area for security personnel to monitor and control access to a site. Guard houses can be found in a variety of locations, from construction sites and parking lots to military bases and industrial facilities. In recent years, modular guard houses have gained popularity due to their versatility, affordability, and ease of construction. Read More…

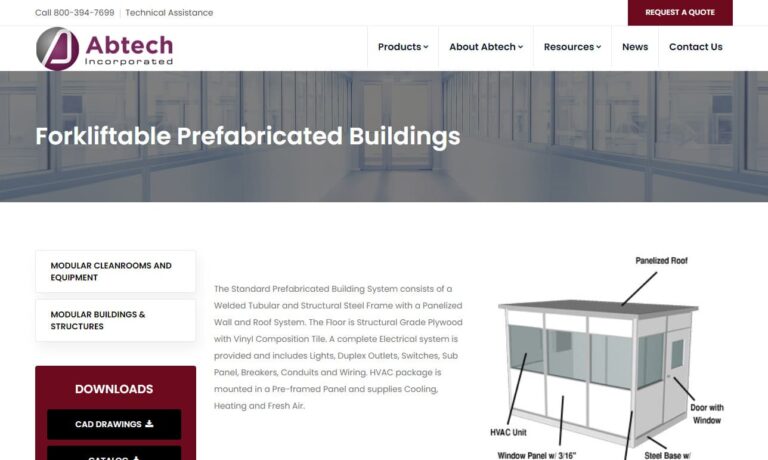

As a modular building manufacturer, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

We offer a wide variety of affordable modular buildings for your convenience. Our engineers are determined to bring you a product with a great value and exceptional customer service. We have been around since 1954 providing portable buildings that are made out of steel.

Our booths and partitions are available in solid surface, stainless steel, solid plastic, solid phenolic, high pressure laminate, and metal powder coated. Our washroom accessories also include combo towel waste units, paper towel dispensers, waste receptacles, soap dispensers, mirrors, warm air hand dryers, toilet tissue dispensers, toilet seat cover dispensers, grab bars, bathroom accessories,...

Morgan Buildings can meet just about any modular building need. For over 60 years and 3 generations Morgan has been a pioneer and leader in modular design and construction. As a fully integrated family-operated company we design, build, transport and install modular buildings around the country and the world. From guard houses to 2-story housing complexes and everything in between we have the...

Donobrog has been a leading supplier of high-quality prefabricated modular buildings and modular offices since 1985. We offer single offices, 2-story multiunit enclosures and noise enclosures in a variety of sizes, styles and configurations. Call today for more information!

At Wilmot Modular Structures, Inc., we take pride in providing innovative modular building solutions that meet the diverse needs of our clients across a wide range of industries. We design, build, and deliver high-quality modular facilities that offer the flexibility, speed, and cost efficiency that today’s projects demand.

More Guard House Manufacturers

Components, Manufacture & Transport of Guard Houses

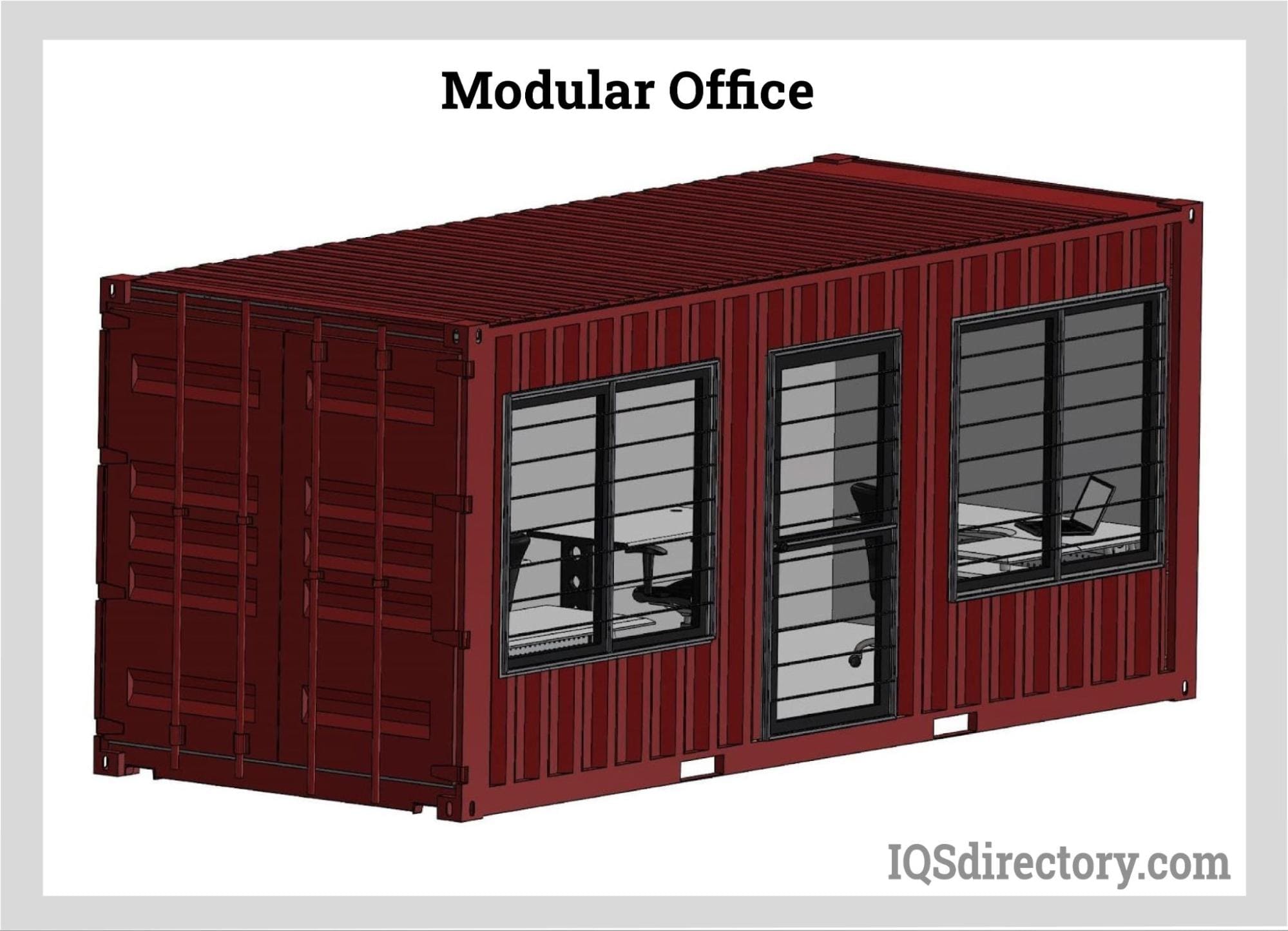

Modular guard houses, also referred to as security guard booths, sentry boxes, or prefabricated security buildings, are manufactured off-site in a controlled factory setting before being transported and professionally assembled on-site. This streamlined approach to manufacturing and installation ensures consistent quality control, faster project completion times, and minimized site disruption. If you’re exploring guard house solutions for your business, facility, or construction site, understanding the core manufacturing process, component options, and transport logistics is essential for making an informed purchase decision.

Modular Guard House Components

The modern modular guard house consists of several key structural and security components, all engineered for durability, functionality, and user comfort. These main components include:

- Wall panels

- Roofs

- Floors

- Doors

- Windows

- Insulation

- Electrical and lighting systems

- HVAC (heating, ventilation, air conditioning) options

- Integrated security features (cameras, alarms, intercoms)

- Workstations and ergonomic furniture

Wall Panels

Wall panels are typically fabricated from steel, aluminum, wood, or precast concrete. High-quality wall panels can be specified to be weather-resistant, fire-resistant, and bullet-resistant, meeting the strictest standards for perimeter security and employee safety. For added protection, some guard booths use sandwich panel construction with internal insulation and steel skins, offering superior energy efficiency and sound attenuation.

Roofs

Roof construction for security guard booths can vary widely. Flat, sloped, or gabled roofs are available, depending on climate and architectural requirements. Materials such as steel, aluminum, or composite roofing panels deliver superior weather protection and durability. Roofs may be designed to support additional features like surveillance cameras, exterior lighting, solar panels, and even lightning protection systems.

Floors

Floors in modular guard houses are generally made from concrete, steel, or marine-grade plywood. For facilities requiring heavy-duty performance, reinforced floors can support safes, security equipment, or even small machinery. Non-slip coatings and raised flooring systems are frequently used to enhance safety and simplify cable management.

Doors

Secure access is critical in every guard house application. Door options include heavy-gauge steel, aluminum, or reinforced fiberglass, often featuring advanced security features like electronic locks, biometric scanners, card readers, and intercoms. Fire-rated and bullet-resistant doors are available for high-security installations, and all doors are typically designed for easy operation and ADA compliance.

Windows

Windows in security guard houses provide essential visibility, ventilation, and occupant comfort. Manufacturers offer a range of window types, including fixed, sliding, and operable designs, with glazing options such as tempered glass, polycarbonate, or laminated bullet-resistant glass. Tinted or reflective coatings are often specified for privacy and solar control, while security grilles and shutters can be added for extra protection.

Insulation

Effective insulation is crucial for maintaining a comfortable interior temperature and reducing noise intrusion, especially in harsh climates or high-traffic environments. Guard houses may utilize fiberglass batt insulation, rigid foam, spray foam, or insulated sandwich panels. Fire-resistant and soundproof insulation options are available to meet unique site requirements and regulatory codes.

Electrical & Lighting Systems

Modern guard houses are prewired at the factory for lighting, power outlets, communications, and integrated security systems. LED lighting, energy-efficient fixtures, emergency backup power, and surge protection are commonly included. Custom electrical layouts can accommodate specialized electronics, communications gear, and control panels.

HVAC Options

To ensure year-round comfort for security personnel, many modular guard houses come equipped with built-in HVAC units. Options include wall-mounted air conditioners, heaters, ventilation fans, or even ductless split systems. Proper ventilation and climate control are especially important for guard shacks in extreme weather regions or for booths used as 24-hour security stations.

Integrated Security Features

To maximize safety and operational efficiency, most manufacturers offer a range of integrated security features, such as CCTV cameras, motion detectors, intrusion alarms, duress buttons, access control systems, and intercoms. These systems can be tailored to your facility’s unique needs, supporting everything from basic access control to advanced real-time monitoring and emergency response protocols.

Workstations & Ergonomic Furniture

A well-designed guard house interior often includes built-in workstations, counters, storage cabinets, and ergonomic seating. These features enhance productivity and comfort for security staff, enabling them to monitor multiple screens, manage visitor logs, or respond quickly to emergencies.

Manufacturing and Transportation Processes

Modular guard houses are manufactured off-site using state-of-the-art fabrication techniques, precision welding, and advanced quality control protocols. The assembly process typically involves joining wall, floor, and roof modules, pre-installing windows, doors, insulation, and wiring, and then finishing the interior and exterior to your specifications.

Once fabrication is complete, the prefabricated modules are loaded onto flatbed trucks or specialized trailers for transportation. Thanks to their modular design, these security buildings can be delivered in one or more shipments and quickly assembled on location—often within hours or a few days—using cranes, forklifts, and skilled installation crews. This efficient approach dramatically reduces on-site labor, minimizes construction delays, and helps keep projects on schedule and within budget.

Looking to streamline your security infrastructure? Discover more about guard house variations and find the best solution for your facility.

Variations of Guard Houses

The security industry offers a wide variety of guard house designs, each tailored to specific use cases, buyer needs, and environmental challenges. When selecting a guard house, it’s important to match the structure’s features and capabilities to your operational requirements, level of risk, and future scalability needs.

Types of Guard Houses

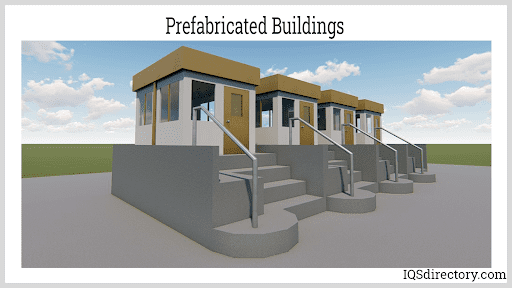

- Portable Guard Houses / Mobile Guard Booths: Lightweight and easy to relocate, these units are ideal for construction sites, parking lots, events, and temporary security details. Their compact footprint and rapid deployment make them a popular choice for organizations requiring flexibility.

- Permanently Installed Guard Houses: Designed for long-term installations at government facilities, corporate campuses, manufacturing plants, airports, and military bases. These structures can be customized with advanced security features and architectural finishes to match existing buildings.

- Bullet-Resistant Guard Booths: Engineered to protect personnel in high-threat environments, these booths use ballistic-rated materials and glazing to withstand firearm attacks.

- Weatherproof Guard Houses: Outfitted with reinforced roofing, weather-sealed windows/doors, and heavy-duty insulation, these buildings are suited for harsh climates and outdoor sites exposed to rain, snow, wind, or extreme temperatures.

- Custom Guard Houses: Manufacturers can design and build guard houses to any size, floor plan, or security specification, accommodating ADA accessibility, multi-person teams, integrated restrooms, or specialized surveillance equipment.

Some guard houses are engineered for rapid mobility with built-in lifting eyes or forklift pockets, allowing you to move them as your security needs change. Others feature permanent foundations for maximum stability and longevity. The choice between portable and permanent guard houses is often determined by your site’s infrastructure, anticipated security threats, and budget constraints.

Materials and Construction Techniques

Guard houses can be fabricated from steel, aluminum, concrete, wood, or composite panels. Steel guard booths offer unmatched durability, fire resistance, and tamper-proof construction, while aluminum provides a lightweight, corrosion-resistant alternative for coastal or humid regions. Concrete guard houses are favored for blast resistance and long service life, while wood and composite materials may be used for aesthetic or budget-sensitive projects.

Looking for guidance on which guard house material is best for your environment? Ask: What are the pros and cons of steel vs. concrete guard houses for high-security sites?

Considerations Regarding Guard Houses

Before investing in a guard house, it’s important to consider several key factors affecting long-term performance, safety, and cost-effectiveness:

- Weather Resistance: Guard houses should be engineered to withstand local weather conditions. For locations prone to heavy rain, snow, high winds, or extreme heat/cold, look for weather-sealed construction, corrosion-resistant materials, and robust insulation.

- Security Standards: Ensure your guard house meets all applicable fire codes, ballistic resistance standards, and access control requirements. Ask about UL, ASTM, or NIJ ratings for bullet-resistant panels and glazing.

- Ergonomics & Comfort: The health and productivity of security personnel depend on interior comfort. Specify adequate lighting, ventilation, HVAC, and ergonomic furnishings for 24/7 staffing.

- Mobility vs. Permanence: Decide whether you need a portable guard house or a permanent installation. Mobility is crucial for temporary job sites and events, while permanent booths offer maximum durability and integration.

- Customization: Look for manufacturers that offer easy customization of size, layout, security features, and finishes to fit your operational requirements and site branding.

- Maintenance Needs: Consider ease of cleaning, component replacement, and long-term durability. Request maintenance guidelines from your manufacturer.

- Cost & Lead Time: Modular guard houses generally offer lower total installed cost and faster delivery than site-built security structures. Compare quotes and lead times from multiple vendors to ensure best value.

Want to compare your options? Search: How do portable guard houses differ from permanent security booths for commercial sites?

Benefits of Guard Houses

Guard houses offer a diverse range of benefits for organizations seeking to enhance facility security, control access, and support security professionals. Key advantages include:

- Increased Security & Safety: Guard houses establish a clear, monitored entry point, deterring unauthorized access and providing a physical barrier between the public and sensitive areas. Enhanced with security cameras, alarms, intercoms, and access control, these buildings form an integral part of any layered security strategy.

- Operational Flexibility: Modular guard houses can be easily transported, relocated, or reconfigured as your site’s needs evolve. This adaptability is perfect for construction projects, event venues, and expanding campuses.

- Cost Effectiveness: Prefabricated guard houses reduce both construction time and labor costs compared to traditional site-built structures. They also minimize site disruption, allowing normal operations to continue during installation.

- Customizable Features: From bullet-resistant glazing to integrated surveillance systems, guard houses can be tailored to any security level or user requirement. Optional amenities include restrooms, break areas, and ADA-accessible layouts.

- Professional Appearance: Modern guard houses can be finished to match your corporate branding or architectural style, making a positive impression on visitors and staff.

- Improved Staff Performance: A comfortable, well-equipped guard booth improves morale, reduces turnover, and enhances the effectiveness of your security team.

Curious about how guard houses can fit into your security plan? Ask: What are the ROI benefits of modular guard houses versus traditional site-built security stations?

Applications of Guard Houses

Guard houses play a critical role in maintaining security, controlling access, and supporting surveillance across a broad range of industries and facility types. Common applications include:

- Security Checkpoints: Airports, government buildings, border crossings, and military bases rely on guard booths to screen vehicles and personnel entering secure areas.

- Construction Sites: Portable guard houses provide temporary security, manage deliveries, and protect valuable assets and equipment.

- Parking Lots & Garages: Guard shacks monitor vehicle entry/exit, enforce parking rules, and assist visitors.

- Educational Campuses: Schools and universities use guard houses to enhance student and staff safety, verify visitor access, and deter unauthorized entry.

- Healthcare Facilities: Hospitals and clinics utilize security booths to manage access, support emergency response, and ensure patient privacy.

- Corporate & Industrial Properties: Factories, warehouses, and office complexes employ guard houses to secure perimeters, monitor deliveries, and support loss prevention programs.

- Event Venues & Stadiums: Temporary guard booths help control crowds and manage ticketing at concerts, festivals, or sporting events.

- Residential Communities: Gated neighborhoods and apartment complexes use guard houses to provide 24/7 security and welcome residents and guests.

- Retail & Commercial Centers: Guard booths assist with loss prevention, monitor deliveries, and support emergency coordination.

Wondering how a guard house could improve access control at your site? Explore: What security booth features are essential for schools, hospitals, or industrial facilities?

Choosing the Correct Guard House Manufacturer

Selecting the right guard house manufacturer is vital for achieving the desired balance of security, functionality, cost, and aesthetics. Here are the top factors to consider when evaluating manufacturers and suppliers:

- Experience & Reputation: Look for companies with a proven track record in the security building industry. Research customer reviews, completed projects, and years in business.

- Product Range: Does the manufacturer offer a wide selection of standard models, custom designs, and specialty security features?

- Quality Assurance: Verify that the manufacturer uses high-grade materials, follows strict quality control protocols, and meets or exceeds relevant certifications and standards.

- Customization Capabilities: Can the supplier tailor the guard house to your precise needs, including size, layout, finishes, and integrated security systems?

- Lead Time & Delivery: Ask about standard production times, delivery schedules, and installation support to ensure your project stays on track.

- Warranty & Support: A reputable manufacturer should offer comprehensive warranties and responsive customer service for ongoing maintenance and repairs.

- Turnkey Solutions: Some manufacturers provide turnkey guard house solutions, including site assessment, permitting, foundation work, installation, and after-sales support.

- Value & Pricing: Compare quotes from multiple vendors to ensure competitive pricing and best overall value for your investment.

To ensure you have the most positive outcome when purchasing a guard house, compare several companies using our directory of guard house manufacturers. Each guard house manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each guard house business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple guard house companies with the same form and begin your security upgrade today.

Ready to take the next step? Ask: How do I choose the right guard house manufacturer for my project’s security, customization, and budgeting needs?

Frequently Asked Questions: Guard Houses & Security Booths

What are the most popular features in modern guard houses?

Top features include bullet-resistant panels, energy-efficient HVAC, integrated surveillance systems, electronic access control, ergonomic interiors, ADA compliance, and custom branding.

How can I determine the right size for a guard house?

Consider the number of occupants, required equipment, anticipated visitor flow, and any additional uses (restrooms, break areas, or storage). Manufacturers can provide recommendations based on your site assessment and operational needs.

Can guard houses be relocated?

Yes, most modular and portable guard houses are designed for easy relocation. Check with your supplier for details on transport, lifting points, and reassembly procedures.

What security certifications should I look for?

Look for guard houses that meet UL, ASTM, or NIJ standards for bullet resistance, fire safety, and structural durability. Ask your provider for documentation and compliance details.

How long does it take to install a guard house?

Most modular guard houses can be delivered and installed within a few days, depending on site preparation and customization level. This rapid deployment is a major advantage over traditional construction.

Still have questions? Contact our team or browse our guard house variations section for more details on features, applications, and current industry best practices.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services