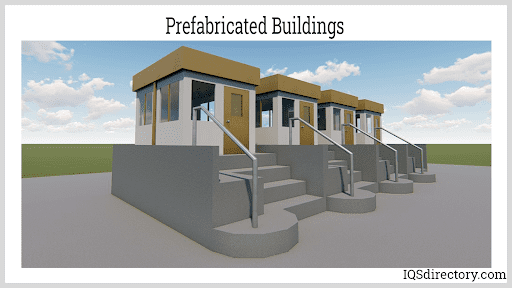

Prefab shelters are among the most functional modular building systems as they offer extreme simplicity in design providing basic shelter at a very cost-effective rate. Read More…

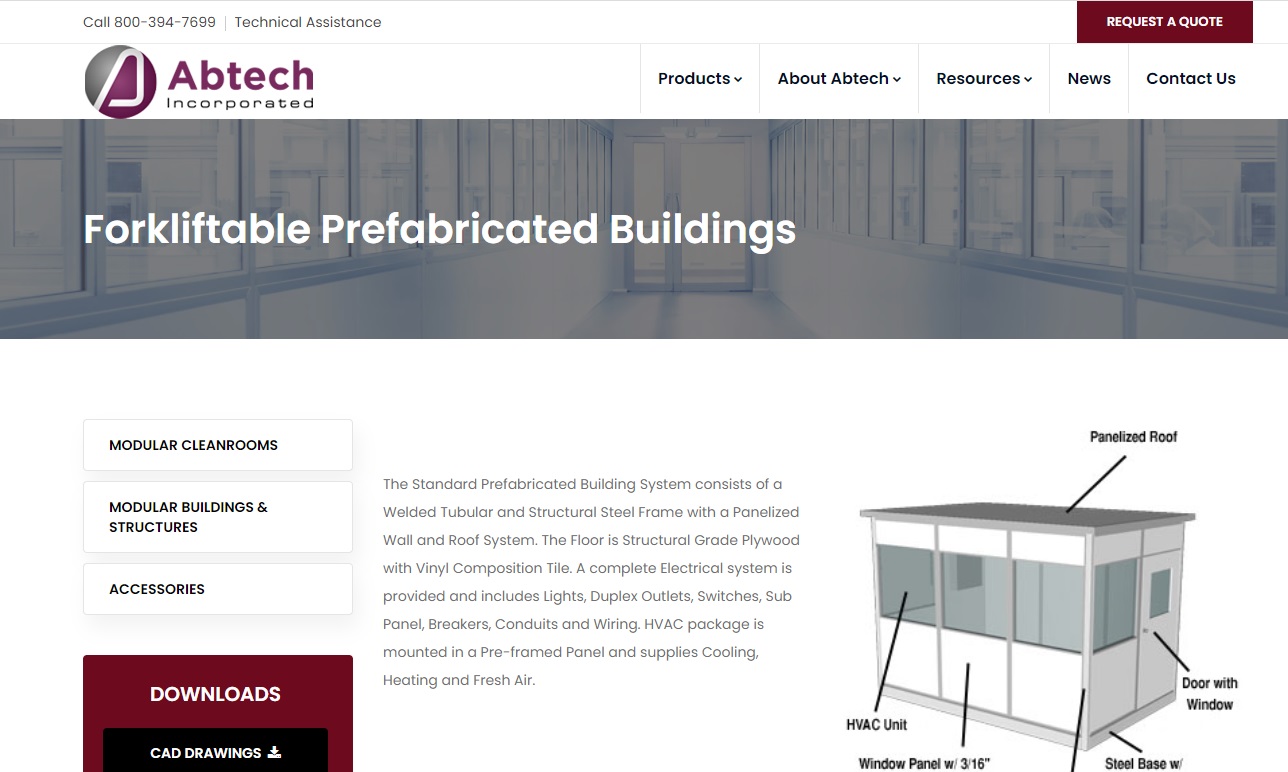

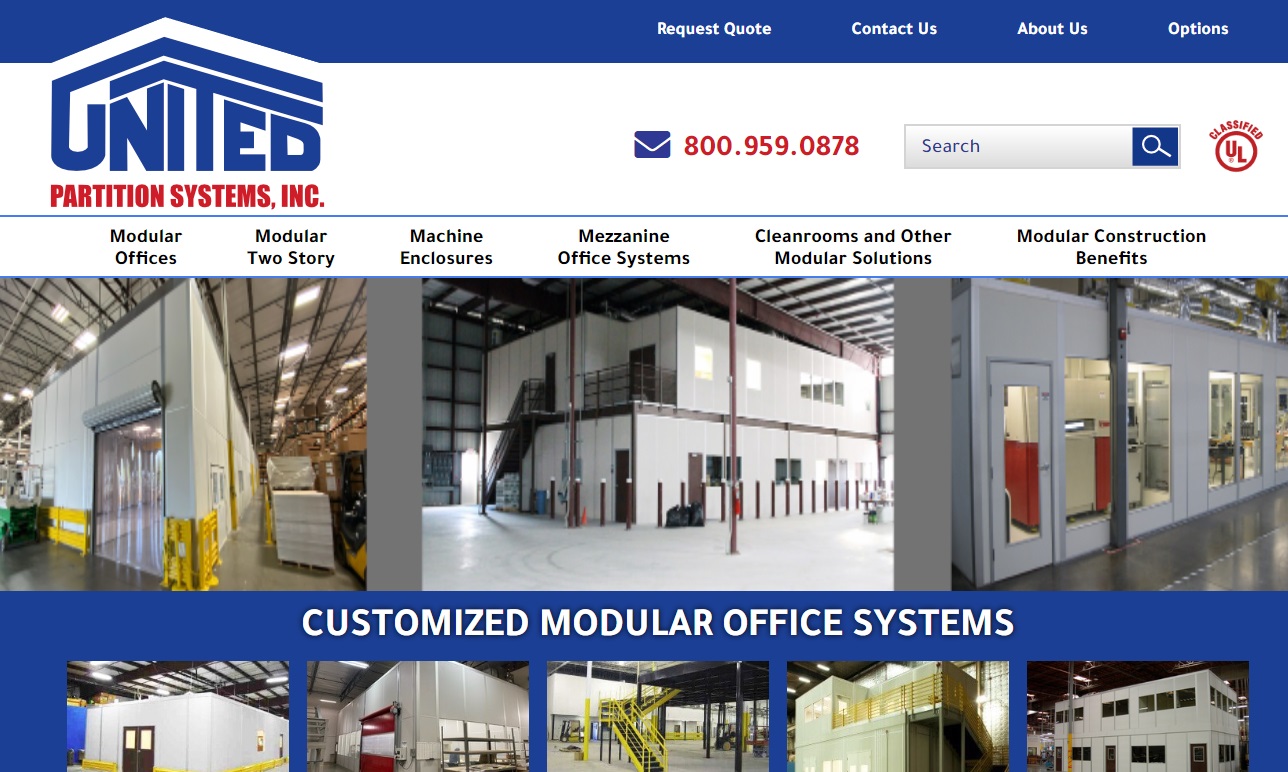

As a modular building manufacturer, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

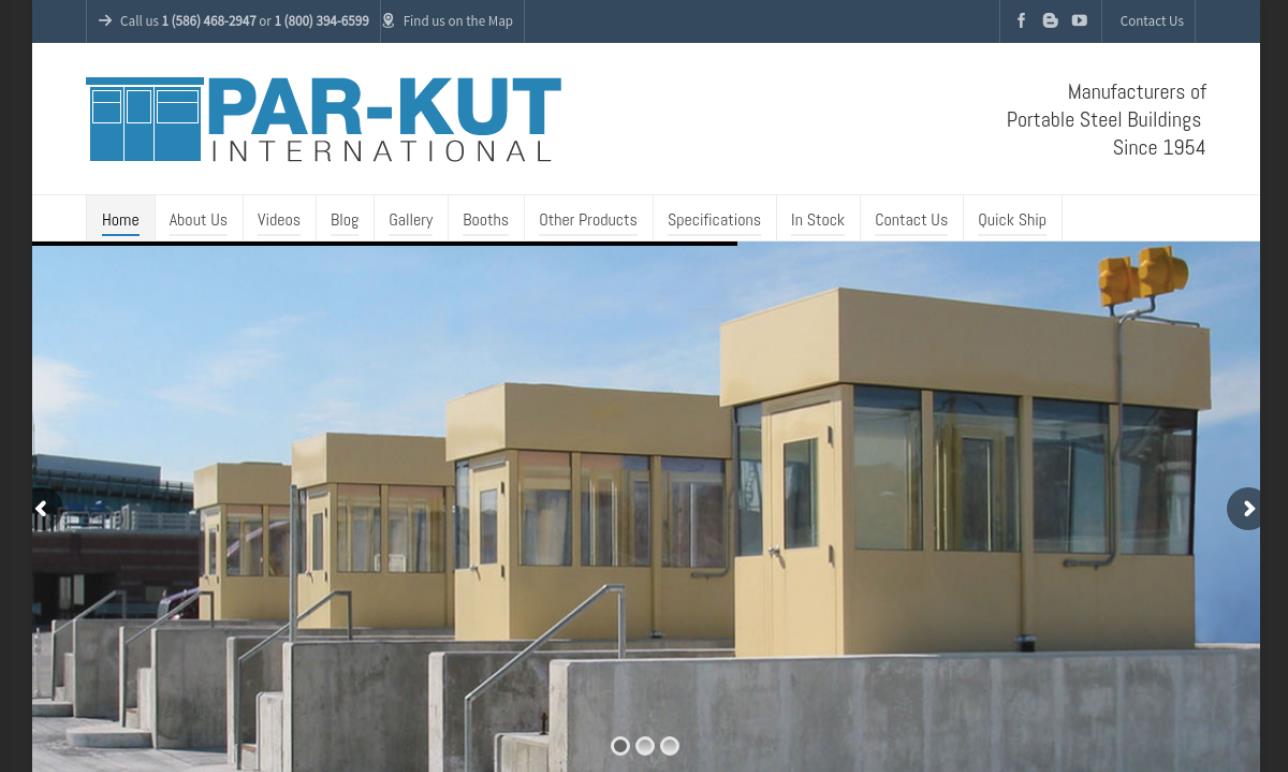

We offer a wide variety of affordable modular buildings for your convenience. Our engineers are determined to bring you a product with a great value and exceptional customer service. We have been around since 1954 providing portable buildings that are made out of steel.

Our booths and partitions are available in solid surface, stainless steel, solid plastic, solid phenolic, high pressure laminate, and metal powder coated. Our washroom accessories also include combo towel waste units, paper towel dispensers, waste receptacles, soap dispensers, mirrors, warm air hand dryers, toilet tissue dispensers, toilet seat cover dispensers, grab bars, bathroom accessories,...

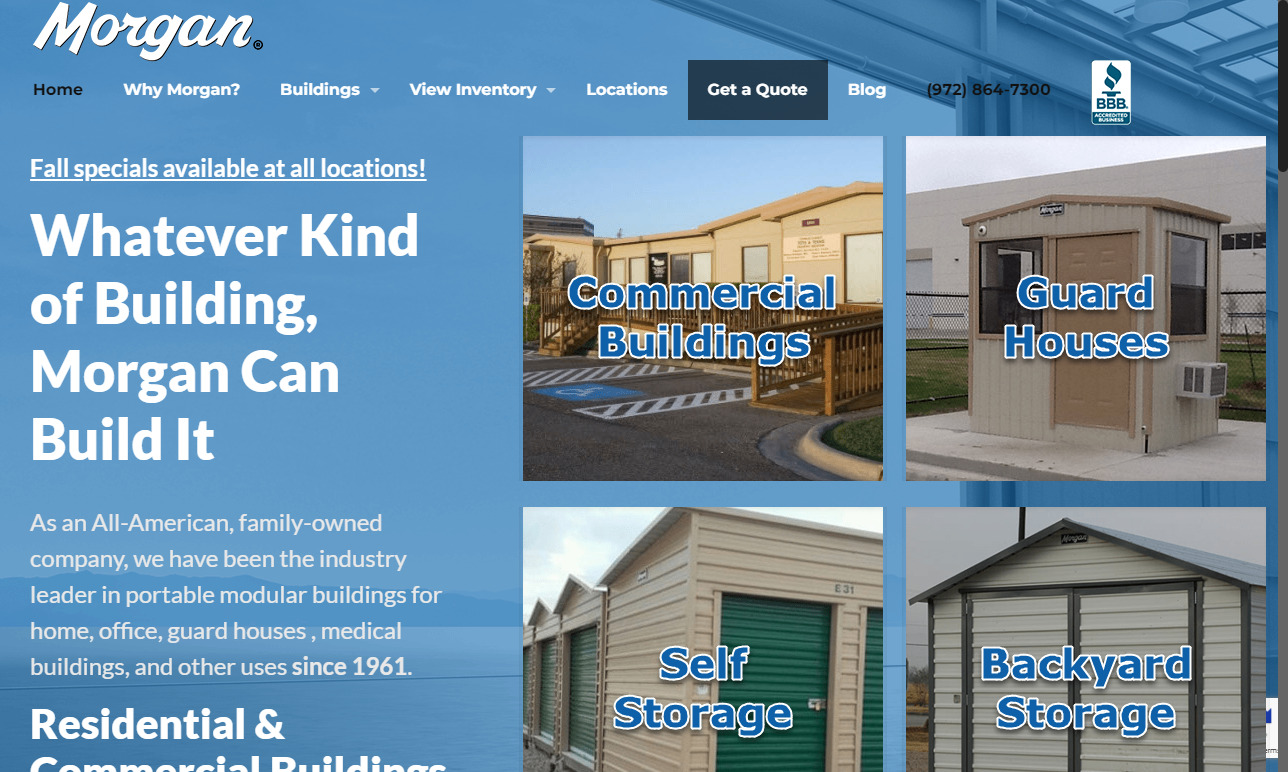

Morgan Buildings can meet just about any modular building need. For over 60 years and 3 generations Morgan has been a pioneer and leader in modular design and construction. As a fully integrated family-operated company we design, build, transport and install modular buildings around the country and the world. From guard houses to 2-story housing complexes and everything in between we have the...

At Boxx Modular, we specialize in delivering innovative modular building solutions tailored to meet the diverse needs of our clients. With years of experience in the industry, we've established ourselves as pioneers in the field, continuously pushing the boundaries of what's possible with modular construction. Our extensive range of products encompasses a wide variety of modular buildings,...

If you are in need of a modular building then you have come to the right place. Customer satisfaction is paramount to our company and we take extra steps to make your experience with us a positive one. We are recognized as a business leader and our success is based off your success. Contact us today for your next project and let us add you to our list of satisfied customers.

More Prefab Shelter Manufacturers

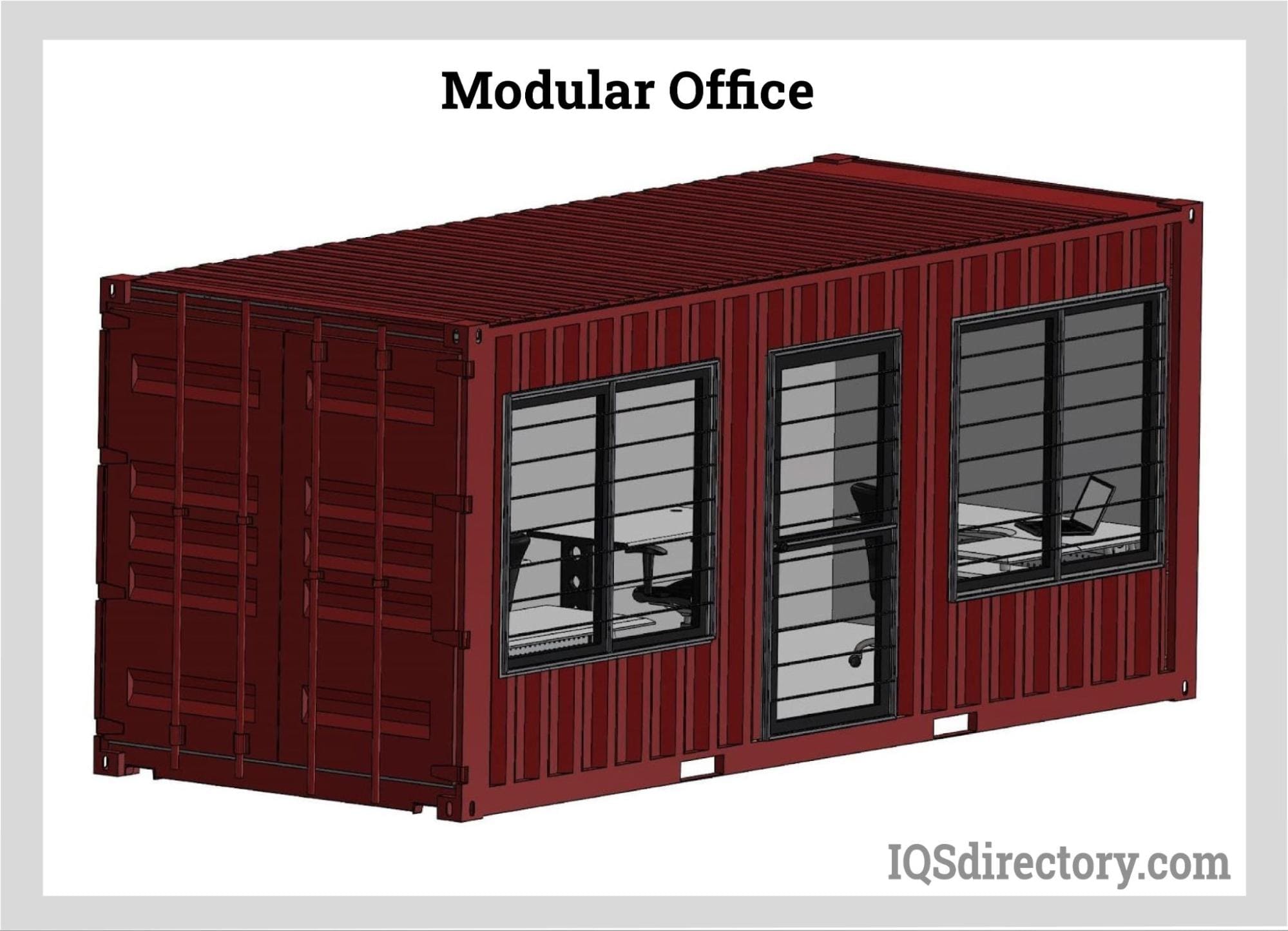

Most prefab shelters are composed of a frame made from steel or aluminum, and a roof. Some shelters have walls of polyvinyl or glass to guard against elements of weather. Able to be installed up to 80% faster than conventional construction thus saving the contractor both material and labor costs, prefab shelters offer durability and low maintenance while withstanding harsh conditions such as extreme temperatures and humidity.

Industries that typically utilize prefab shelters include construction, refrigeration, electronics, storage, automotive, defense, telecommunications and medical. While the most common application that prefab shelters are used for is security enclosures, additional applications include machine enclosures, storage sheds, pump houses, ticket booth, storm shelters, bus stop shelters, guard houses and information booths.

Prefab shelters can easily be designed and engineered to meet the needs of any industry. Prefab shelters can be used permanently or as temporary spaces also known as relocatable buildings. They are able to be used both outdoors and indoors built as part of an existing building system.

Typically consisting of a frame and panels, additions such as windows or shelves can be made to custom fit the prefab shelter for the given application. Custom additions to the design of a prefabricated building may increase the costs significantly, but it may be a worthwhile payoff. Prefab shelter frames can be constructed from materials including lightweight aluminum, precast concrete and bullet proof steel.

Materials that are used to construct the panels include glass and fiberglass reinforced plastic. Both whole prefab shelters and prefab shelter components are manufactured in controlled factory environments. The finished prefab shelter or pieces are then delivered to prepared building sites for installation.

Prefab shelters come complete with all the necessary components, including walls, floor trusses, windows, heating and cooling, plumbing, electrical wiring and interior finishes. Prefab shelter manufacturers provide flexibility and other advantages over site-construction, such as factory-controlled quality and ease of expansion and relocation.

The most significant advantage of prefab shelters is the time saved since they are built according to a carefully monitored timetable within the factory plant. Prefab shelter fabrication uses factory methods to greatly enhance quality and reduce manufacturing time and cost.

55 Gallon Drums

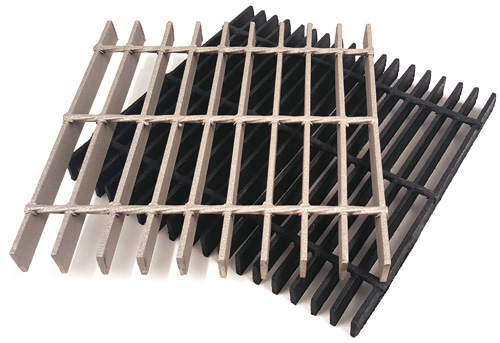

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services